Floating Room Technology

This apartment was constructed using a “Floating Room” to achieve a level of sound insulation that ensures the Marina “stays outside” when you need to be private.

A soundproof floating room, also known as a “room within a room,” is a construction technique designed to achieve maximum sound isolation by decoupling the inner room from the outer building structure. This is accomplished by creating a secondary, isolated structure that is not rigidly connected to the surrounding walls, floor, or ceiling, thereby preventing the transmission of sound vibrations through solid materials. The core principle relies on mechanical isolation, where vibration—the fundamental characteristic of sound—is blocked by eliminating direct structural connections.

This is accomplished by creating a secondary, isolated structure that is not rigidly connected to the surrounding walls, floor, or ceiling, thereby preventing the transmission of sound vibrations through solid materials. The core principle relies on mechanical isolation, where vibration—the fundamental characteristic of sound—is blocked by eliminating direct structural connections.

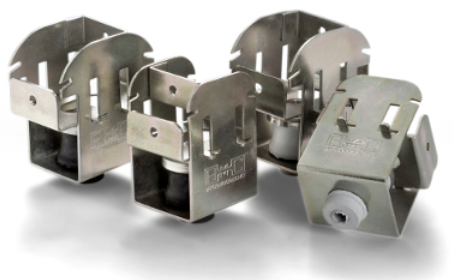

The most effective floating room systems use resilient mounts, or rubber isolators and neoprene pads, to support the inner structure.

The most effective floating room systems use resilient mounts, or rubber isolators and neoprene pads, to support the inner structure.

The Floating Floor use isolators made from high-performance  Sylomer materials, which support the floated floor above the sub-floor with a defined air gap of 50mm. The performance of

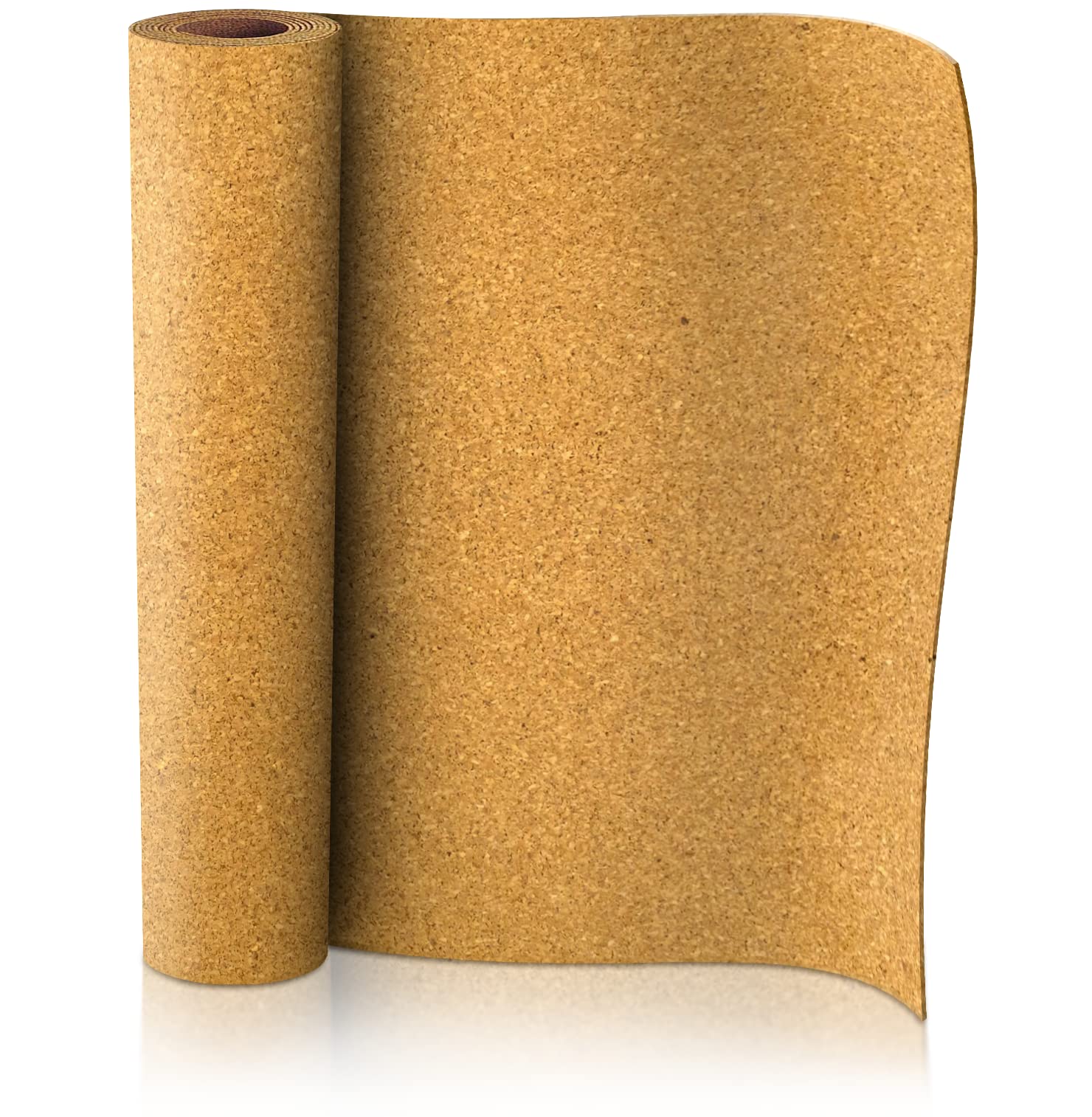

Sylomer materials, which support the floated floor above the sub-floor with a defined air gap of 50mm. The performance of  the floating floor is influenced by the mass of the floated element, the depth of the air gap, and the natural frequency of the isolators. The Floor Floater is a 4mm cork sheet that supports framing members and decouple them from the structure, significantly improving transmission loss and low-frequency definition.

the floating floor is influenced by the mass of the floated element, the depth of the air gap, and the natural frequency of the isolators. The Floor Floater is a 4mm cork sheet that supports framing members and decouple them from the structure, significantly improving transmission loss and low-frequency definition.

For walls and ceilings, floating techniques involve building a secondary structure using acoustic clips (like Whisper Clips), hat channels, and specialized isolators that prevent direct contact with the original structure.  This decoupling creates air gaps that disrupt sound transmission paths. In wall construction, materials such as neoprene rubber and mineral wool are used to float the wall, while mineral wool insulation is placed within the cavities to enhance sound absorption.

This decoupling creates air gaps that disrupt sound transmission paths. In wall construction, materials such as neoprene rubber and mineral wool are used to float the wall, while mineral wool insulation is placed within the cavities to enhance sound absorption.

Ceilings are also floated using ceiling isolators that attach to the existing structure, absorbing vibrations from machinery, music, or footfall. This method is particularly effective in retrofit projects where space is limited.

Ceilings are also floated using ceiling isolators that attach to the existing structure, absorbing vibrations from machinery, music, or footfall. This method is particularly effective in retrofit projects where space is limited.

To ensure complete soundproofing, the entire inner room must be airtight to prevent sound leakage through gaps. This includes using acoustic sealants to seal all joints, seams, and penetrations.

To ensure complete soundproofing, the entire inner room must be airtight to prevent sound leakage through gaps. This includes using acoustic sealants to seal all joints, seams, and penetrations.

![]()